In the state of Oregon, when it comes to the construction of sweat rooms, there are indeed specific regulations governing the use of certain materials. These regulations are in place to ensure the safety, functionality, and durability of the sweat rooms, as well as to protect the health and well-being of the users.

Safety is a paramount concern in sweat room construction. The Oregon building codes stipulate that materials used in the construction must meet certain fire safety standards. For example, any combustible materials used in the interior of the sweat room, such as wall panels or seating, must have a low flame spread rating. This is to prevent the rapid spread of fire in case of an emergency. Additionally, electrical components installed in the sweat room, such as lighting fixtures and heating elements, must be UL-listed and installed in accordance with electrical safety codes to reduce the risk of electrical fires and shocks.

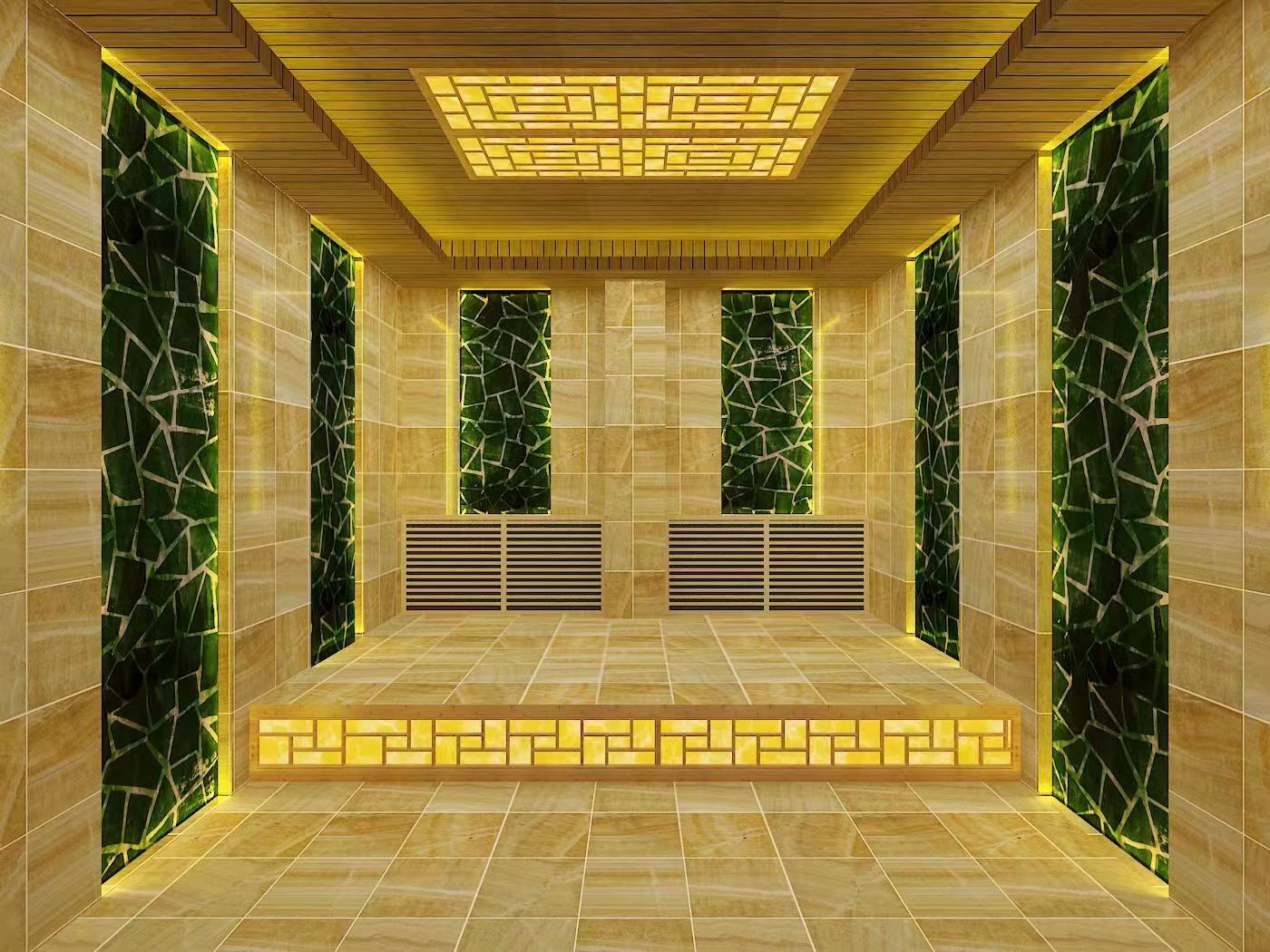

From a hygiene and health perspective, the materials used in a sweat room need to be resistant to mold and mildew growth. In Oregon's regulations, it is often required that materials with anti-microbial properties be used, especially in areas that are prone to moisture accumulation, such as the floors and walls. For instance, ceramic tiles or certain types of synthetic materials that are impervious to water and can be easily cleaned are preferred for flooring. The walls may be required to be made of materials that can withstand the high humidity levels typical in a sweat room and not release harmful substances into the air, as this could potentially affect the respiratory health of the users.

Regarding the structural integrity of the sweat room, the materials used must be able to withstand the thermal and mechanical stresses. The floors need to be able to support the weight of the users and any equipment placed in the room, while also being able to handle the heat and moisture without warping or deteriorating. In Oregon, it is common for regulations to specify the minimum strength requirements for the flooring materials and the type of adhesives or fasteners that should be used to ensure a secure and long-lasting installation. Similarly, the walls and ceiling must be constructed using materials that can maintain their shape and stability over time, even in the humid and warm environment of a sweat room.

In line with the state's commitment to environmental sustainability, Oregon may have regulations regarding the use of environmentally friendly materials in sweat room construction. This could include requirements for using recycled or renewable materials whenever possible. For example, some builders may be encouraged to use bamboo for wall paneling or flooring, as it is a rapidly renewable resource. Additionally, there may be restrictions on the use of certain chemicals and volatile organic compounds (VOCs) in the construction materials to minimize air pollution and protect the indoor air quality of the sweat room, as well as the overall environment.